4/1/2025

Do you know our suppliers? Who are they and where do they come from?

Greetings, fellow roofing enthusiasts! We’re back with a new blog article. Do you know our suppliers? Who are they, and where do they come from? Over the next few weeks,…

3/5/2025

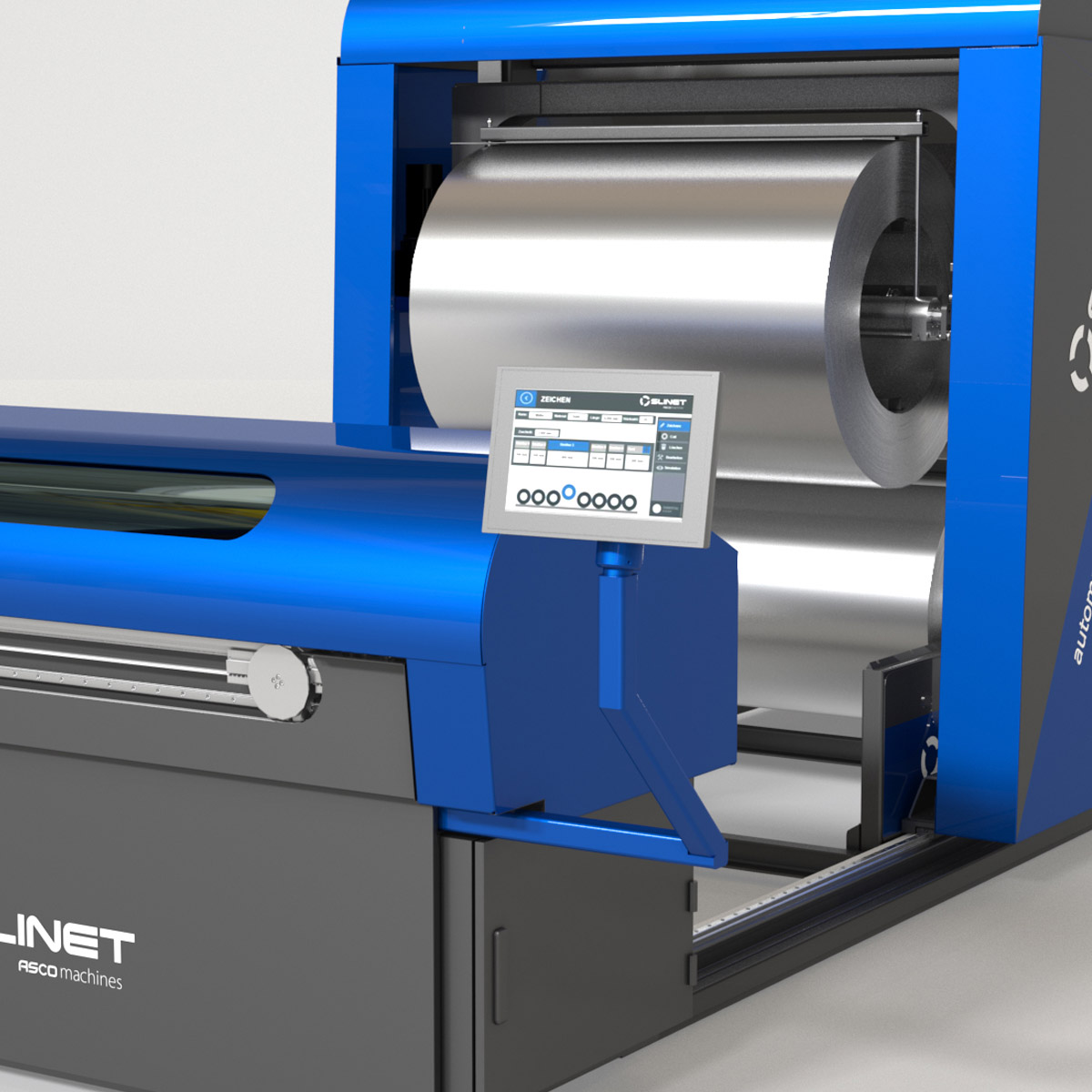

Is it time for a Tool / Machine Health Check?

For our loyal clients who have been with us over the years, you know we love new things! Nothing excites us more than the introduction of a new tool, machine,…