Since 1983, Krehle has specialized in historic building renovations and precision sheet metal processing. They now provide a wide range of high-quality, custom solutions using innovative manufacturing processes and technologies. Their capabilities include producing bent and rounded metal profiles to specific requirements for swift delivery and easy assembly.

They serve various industries and professionals, collaborating closely during planning to showcase technical possibilities and provide reliable project estimates. With decades of experience, they deliver superior products at competitive prices within promised timelines, integrating advanced manufacturing technologies with the unmatched craftsmanship of their team. Whether you need rounded, curved, or bent metal designs, Krehle is ready to collaborate and innovate tailored solutions for your project.

Round Dormers

The round or segmental arch dormer is a common shape in residential construction, featuring round panels on the dormer front and roof covering. Traditionally, creating the necessary curved fillets for these dormers has been challenging and costly due to their complex geometry.

The patented KURVENKEHLE® components revolutionize this process, enabling precise manufacturing and easy on-site installation. With Krehle’s specialized software, it can calculate any valley path accurately using just three measurements from installers. This innovation saves up to 75% in production and assembly time compared to traditional methods.

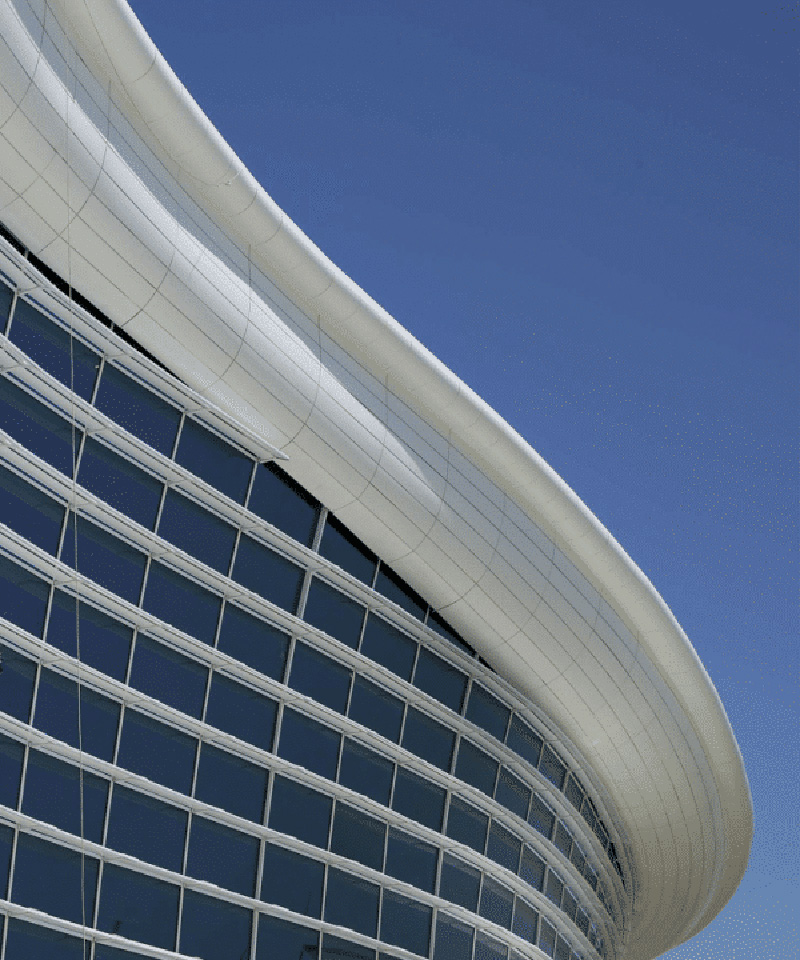

Façade Profiles

- Slotted panels

- Horizontal panels

- Cassette profiles

- and other individual cross-sections

The round façade panels from all manufacturers with different cross-sections, convex and concave, in all radii. Thanks to their special manufacturing techniques, the surfaces remain flat. Even with coated and pre-weathered materials, abrasion-free forming is guaranteed.

If the original panel can no longer be reshaped due to very tight radii, Krehle has the option of producing the panels from smooth sheet metal using the “KREHLE system” and adapting them to the respective appearance of the profile manufacturer.

Roof Edge Profiles

Execution:

- Profile and radius individually according to customer specifications

Example:

- Panel/verge connected at the factory with Krehle patent fold

- Cover/verge individually for individual installation on site (tolerance compensation)

- Attic connections for panels from all manufacturers, factory-connected with Krehle patented rebate

- Internal roof connection for curved wall connection to rounded masonry

- Roof edge profiles barrel roof on rising wall panel

Wall Coverings

Krehle’s expertise lies in crafting custom, horizontally or vertically rounded wall coverings tailored for a variety of uses, including flat roof parapets, balcony enclosures, gable walls, and beyond.

Each production is meticulously tailored to precise measurements, accommodating any radius and material specification. They offer options for inclined designs, variable widths, and flexible side bends. For heritage projects, they specialize in replicating bead formations, ensuring compliance with architectural authenticity and regulations.

- Wall covering horizontal outer curve

- Wall covering horizontal inner curve

- Wall covering vertical convex

- Wall cover vertical concave

- Gable wall covering vertical convex and concave

Window and Cornice Sheets

They specialize in crafting bespoke round window frames of any size and radius, complete with single-piece construction that features seamless integration and no folds or welds.

Full circles are meticulously assembled from two or more circular segments, ensuring a perfect fit with narrow and wide sides. For inclined full circles, Krehle’s design incorporates an additional water guide angle to effectively channel moisture away from the facade, enhancing durability and performance.

- Window sheet vertical semicircle

- Window sheet vertical full circle

- Window sheet horizontal outer curve

- Window sheet horizontal inner curve

- Sill sheet vertical convex

- Sill plate vertical concave

- Sill plate horizontal outer curve

- Sill sheet horizontal inner curve

Box Gutters

Box Gutters – Standard version

- Gutter dimensions according to DIN/EN nominal sizes

- horizontally rounded

- Gutters made in 2 parts, assembled at the factory, for soldering on-site

- Individual lengths vary up to 2700 mm depending on the radius

They offer further options and special designs:

- with individual dimensions according to customer specifications

- Glue-in leg on the rear edge up to max. 80 mm width (depending on the radius)

- Glue-in legs over 80 mm wide with KREHLE patent fold

- with gutter gradient (for the version with glued-in leg)

- with a bead for attaching (for aluminium and stainless steel versions)

- with cover instead of bulge (cheaper)

- vertically rounded

- Sealing soldering at the factory

Gutter Inlet Plates – Standard version

- Inlet sheet for tile roofing (without projection)

- Inlet sheet for metal roofing (with projection)

- horizontally rounded

They offer further options and special designs:

- Version with inclination

- Design with gradient

- Vertically rounded

Profile Shares

Krehle produces standing seam panels for metal roofing in any configuration, featuring over- and under-covering seams. CAD is used for length calculations, seam division, and installation planning.

Their process includes creating dome panels with prefabricated folds, facilitating rapid installation and mechanical folding for a flawless, evenly rounded surface. Special solutions such as 3D cambering and self-supporting dome structures with internal TIG-welded flanged folds are also available, ensuring smooth, seamless finishes without manual creasing marks.

- Barrel Roof

- Cone

- Dome

Profile Bending

Specialize in swiftly meeting dynamic requirements with high precision and flexibility, offering a wide range of economical hollow profiles that seamlessly transition from curved to straight forms.

- Steel, stainless steel, and aluminium

- Round tubes and steel bars

- Square tubes

- Angle and flat steels

- Individual toolmaking

- Short production times

- Small series

- Prototypes

Round Bending

They specialize in delivering high-precision, flexible profiles quickly and efficiently, accommodating lengths up to 3000 mm and radii up to 150 mm. Their capabilities include seamlessly merging different radii and rounding edges for a polished finish.

Materials they work with include:

- Aluminium (up to 3.0 mm)

- Steel (up to 2.0 mm)

- Stainless steel (up to 1.5 mm)

- Aluminium composite panels (up to 4.0 mm)

- Titanium zinc (up to 1.5 mm)

- Copper (up to 3.0 mm)

- Brass (up to 2.0 mm)

Krehle offers specialized options such as conical designs, varying material thicknesses for shorter components, and tight radii achievable through CNC stamping and bending processes up to 4000 mm. Their commitment to precision ensures the highest repeatability, including contour matching to templates and custom designs.

Photo credit: All Krehle images are copyrighted to Krehle GMBH and Michael Christian Peters.