Details

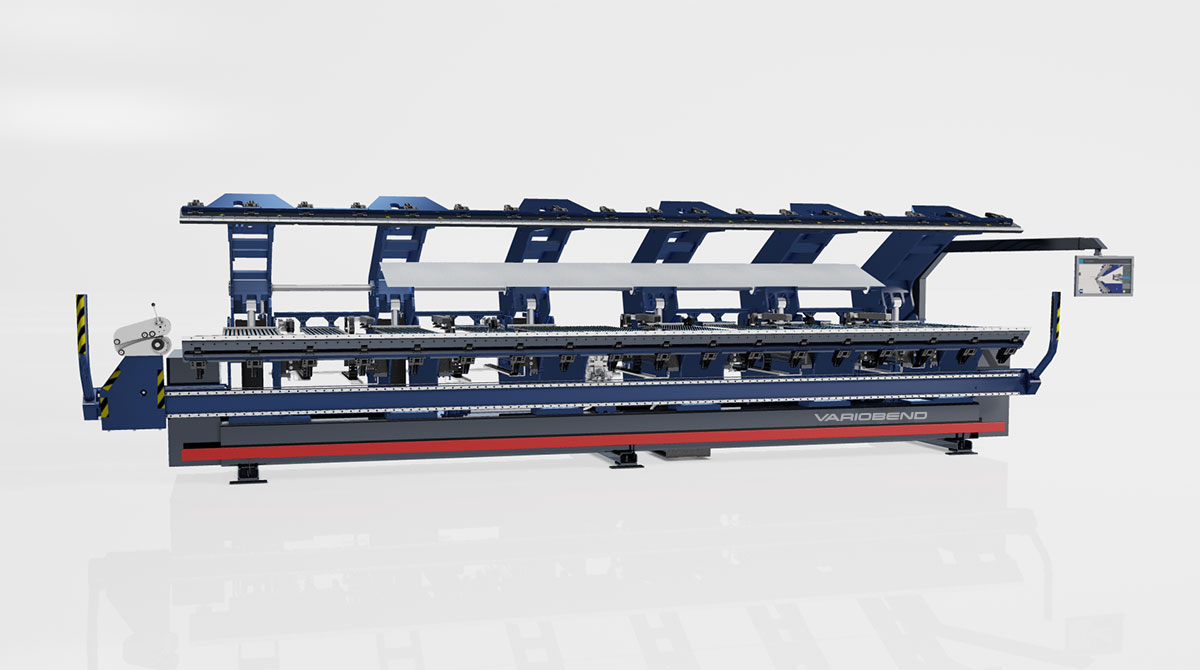

VARIOBEND UP and DOWN Folder – model series DB 1.5

The DB models combine perfect interaction of precision and high speed. Using the VARIOBEND UP and DOWN Folder, you are unrivalled productive from programming to bending.

VARIOBEND UP and DOWN Folder of type DB is a high-performance long-length bending machine fitted with two folding beams. VARIOBEND innovations, such as the conical bending and slotting of profiles, the large opening height of the clamping beam, the segmented bending and clamping beams made of high-strength steel as well as the patented bending system with its inclined bending beams belong to the basic equipment of DB. The worldwide unique turning device is available for this model series as well.

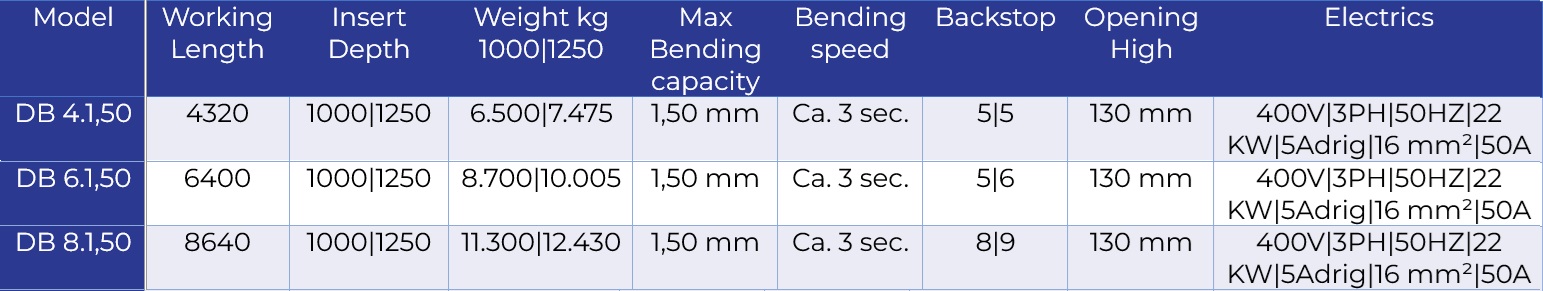

The models are available in lengths of 4 to 12 metres and have a bending capacity of 1.5 mm to 2.0 mm of steel sheet.

Apart from its high bending performance, the model provides numerous technical possibility which lives up to the trend in every respect to produce evermore precise bent parts. Apart from the precision of the edge parts, the focus of every purchase decision is on the production time as well. During a change of the bending direction, for example, the required forward or backward movement of the clamping beam, the positioning of the back gauge and the closing of the clamping beam is carried out at the same time and in a correspondingly tight time slot. In combination with the servo technology used, these unique dynamics cause impressive and especially highly efficient movement patterns.

The electric clamp beam crowning is an outstanding feature. The fully automatic crowning system completely eliminates overbending at the outer sides of the edge parts. This is achieved by positioning highly-precise servo drives independently from each other to each machine stand depending on type and thickness of material. If the user requests additional individual corrections, they can be carried out easily and very user-friendly by means of the VARIOBEND touch control. The clamp beam crowning and the servo technology is available for model series DB as an optional feature.

STANDARD EQUIPMENT

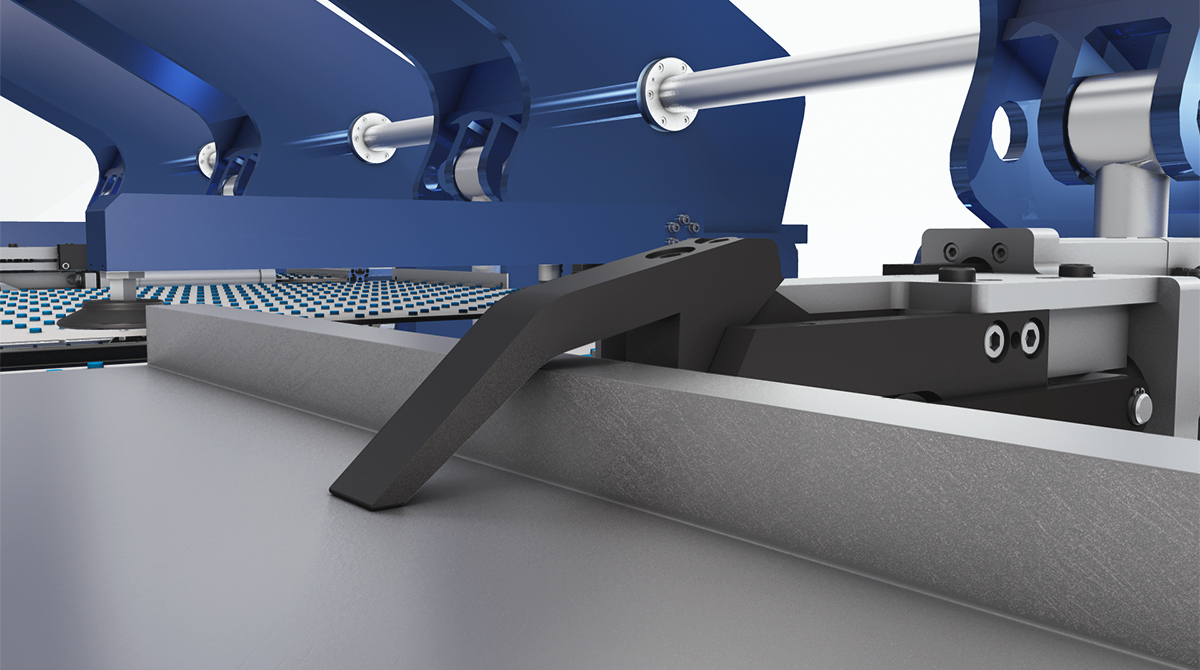

- Patented bending system with angularly positioned bending beam

- Hydraulic Slitter up to 2,00 mm steel

- Variobend 3D Touch Control

- Variobend Office Software package

- CNC – back gauge driven by ballscrews

- Extra hardened segments for clamping and bending beam

- Multifunction Pedal for bending, clamping and cutting operation

- Insertion depth 1.000 mm

- Variobend control on the swivel arm

- Taper back gauge incl. stick together function

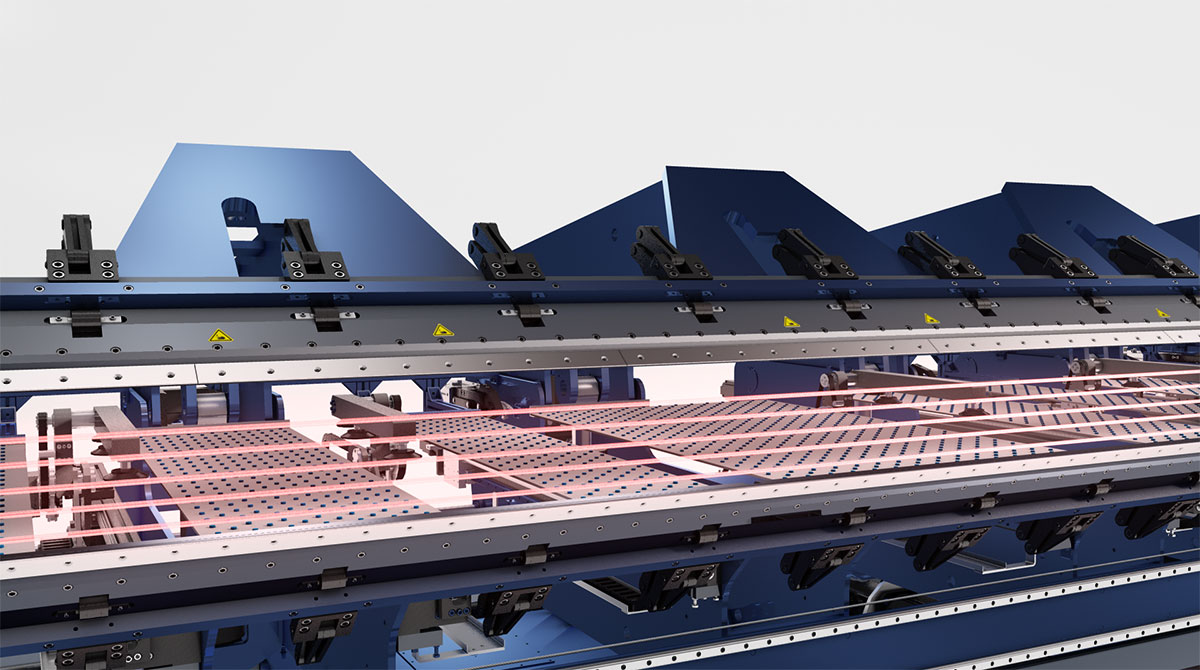

- Safety package incl. Light beam protection

Tools/Options

Extra Equipment:

Control panel on roll-top desk

Servo drive motor for 1,50 mm models

- Variobend RP-Technology (Start|Stop)

- Higher output because of approximately 30 % more bending speed

Gripper stations incl. back gauge fingers

- Variobend Gripper Stations Number of grippers: 4 meter|3 pcs, 6 meter|4 pcs., 8 meter|5pcs, 10 meter|6pcs

- Gripper min. size: 35 mm

- Overgrippable size: 38 mm

Gripper station for short-length

- Variobend additional Gripper Stations

- Gripper min. size: 35 mm, short length distance 600 mm

- Overgrippable size: 38 mm

Full automated crowning system

- Variobends full automated crowning system. Every stand of the machine is driven by a separate Servo-Drive. The crowning system is operated by the Variobend Touch Control. The Variobend Touch control shows the exact positioning of each stand. The operator can easily move each stand. This system ensures perfect bending results over the complete working length.

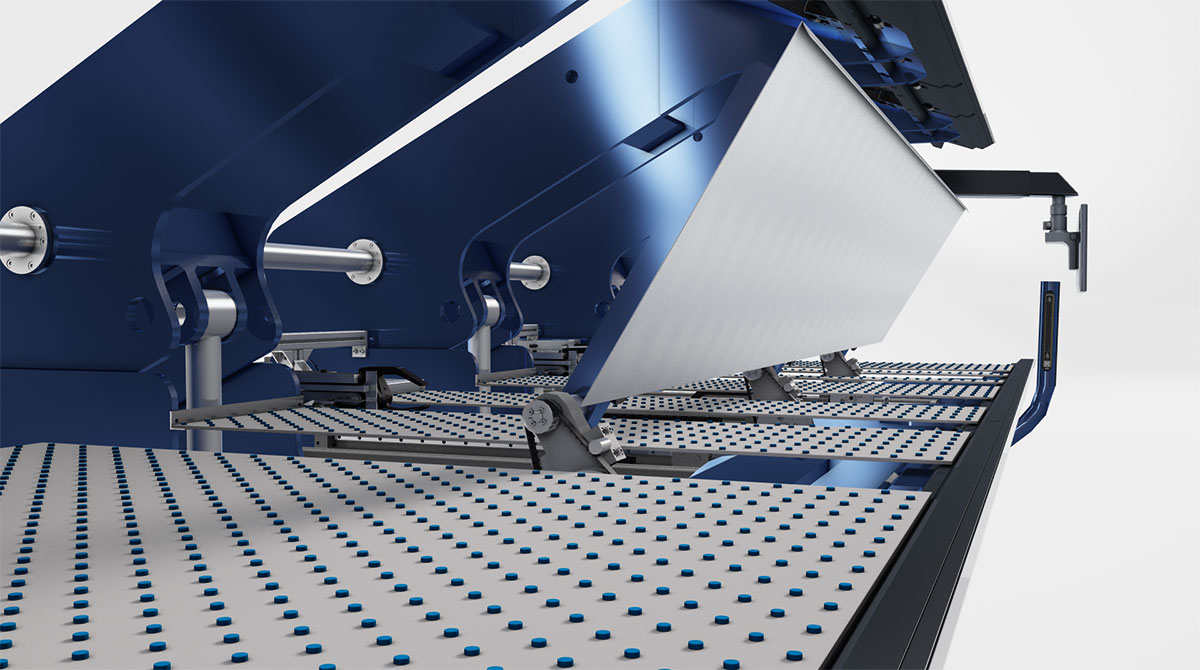

Flipping device

- Technical Information Turning profiles:

- + with a blank of 220-700 mm

- + over the entire working length

- + up to the maximum material thickness

Variobend roll former

- Max. Rollforming capacity:

- 0,8 mm steel (400 N/mm²)

- 1,0 mm alu (190 N/mm²)

- 0,5 mm stainless steel (600 N/mm²)

- Smallest possible shenk length with rollforming:

- A: 45 – 60 mm

- B: max. 25 mm

Cutting device with automated Overlap- and Gap adjustment by Servo technology

- Slitter incl. automated distance and gap adjustment

- Both sides sharpened

- Up to STEEL | ALU| STAINLESS STEEL = 2,50 mm | 3,00 mm | 1,50 mm

Extra gripper opening circle

- With this function grippers combined as groups can be opened separately.

Fence behind the machine

- Moveable L – Shape

Variobend digital package

The newly introduced digital package from Variobend offers you the best possible networking of your machine.

Overview of digital package Variobend

- Networking Variobend and Slinet

- Incl. PDF export with square meters and weight information of the flashings

- Incl. DXF import on the Variobend

- Including DWG import on the Variobend

- Including barcode reader

- Including interface for third-party software such as Bendex, NuIT or Sema

- Including XML interface for integration into ERP systems or other software

- Including 3 annual licenses for the Variobend app

- ASCO production software ready

Software

VARIOBEND 4.0 software solutions

Markets are subject to permanent change. In sheet metal forming, this also leads to an ever higher complexity of products and processes. Effective, highly flexible, but also user-friendly solutions are needed. The software solutions of ASCO will help you to get a grip on precisely these challenges, reducing expenses in the process as well. Networked production reduces the risks of error and increases profitability.

VARIOBEND Pro 4.0

Increase your output

Many orders and small lots mean that your machine operators or programmers must program faster – error-free! With VARIOBEND Pro 4.0, you have sufficient time for efficient work preparation. VARIOBEND Pro 4.0 software displays all process steps for an efficient planning process. With VARIOBEND Pro 4.0, you do not program your long-length bending machine or your twin bending machine at the machine but in one or several workplaces parallel to production. This process reduces auxiliary process times distinctly and thus increases the machine availability dramatically. No time-consuming training of the machine. Thus, your VARIOBEND works productively without brakes.

Save time and increase your overall productivity

Once the order has been set up, the data are transferred to the machine paperless. In addition, the production order can be exported as a PDF and can be provided with a unique QR code. This PDF is handed over to the machine operator. The machine operator scans the profile to be produced. By means of the QR scanner, the profile prepared in the office previously is called up with all characteristics and can then be produced immediately. Avoid unproductive times – use the intelligent and highly efficient

VARIOBEND Pro 4.0.

- Modern dashboard for easy navigation

- Clearly arranged profile management

- Import function (CAD file, V-MOBILE, other interfaces SEMA, NuIT, etcetera)

- User-friendly drawing and dimensioning of the profile

- Input of material characteristics (material, thickness, length and number of units)

- 3D animated thumbnails of the profiles

- Automatic cutting pattern calculation including K factor (proof sheet for leg length by bend deformation)

- Automatic bending sequence calculation calculated the ideal bending sequence

- Animated bending procedure to check for collisions

- Calculation tool (estimated bending time*, cut calculation)

- Paperless transmission directly to the machine

- Control of two machines by one computer only

- Preparation of production orders by QR code via PDF

* only for twin bending machines with gripper system

VARIOBEND V-TOUCH | Machine control

As fast as never before – from sketch to bending programme

VARIOBEND V-TOUCH is the only software that combines efficiency and user-friendliness in an unprecedented relationship. The series VARIOBEND TOUCH control stands our for its user-friendliness and a clear structure. Any number of profiles and folders can be set up in profile management. They can be moved, copied or exported by a simple touch. Functions, such as conical bending or slotting of profiles as well as bending simulation, are a standard. The modern 21.5” flat screen in HD resolution permit ideal input and display.

V-TOUCH AT A GLANCE:

- Modern dashboard for easy navigation

- Clearly arranged profile management

- New profiles can be drawn and dimensioned with a finger in a user-friendly way.

- Presentation in 2D and 3D

- Automatic cutting pattern calculation including K factor (proof sheet for leg length by bend deformation)

- Automatic bend sequence calculation to reduce material handling

- In simulation, the complete bending process can be checked for the absence of collision

- Graphic display of the colour or visible side

- Animated bending sequence in 2D to check for collisions

- Prospective bending time calculation *

- Material database for automated angle correction depending on material and thickness

- Cutting programme including conical cut function

- Import and export function

- Interface to several Software solutions (SEMA, BENDEX, NuIT) and merchandise management systems

- Saving of more than 10,000 profiles is possible

Technical data

The DB models combine perfect interaction of precision and high speed. Using the VARIOBEND UP and DOWN Folder, you are unrivalled productive from programming to bending.