Details

Standard Configuration

Software control:

- POS 2000 Professional graphic control and swivelling arm

- Radius function

- Remote maintenance

Clamping beam:

- Clamping beam stroke 500 mm

- Clamping beam geometry 48° or 180°

- Drive: 2 x 2,2 kW (65 mm/sec) axis with recirculated ball screws

- The axis inclination of the clamping beam

- Hydraulic tool clamping device for clamping beam

Folding beam:

- Drive: 2 × 3.0 kW (converter-controlled, 100°/sec)

- Pneumatic tool clamping device for folding beam

- Motorized folding beam adjustment 150 mm

- Motorized folding center adjustment +80/- 20 mm

- The central crowning device, motorized

Bottom beam

- Bottom beam blade ca. 1 100 N/mm2 surface-hardened (nitrated),

one-piece with finger grooves; minimum gauge 10 mm

Back gauge system

- Sheet support table with gauge up to 1600 mm (closed; 2 sectors with pneumatic

lowering device, sheet support table with balls, recirculated ball srews

(+/- 0,1 mm))

Others:

- Footswitch

- Anchor plates, incl. dowels

- Standard machine without folding- and clamping beam tools

- LED status display

- Bottom beam blade, ca. 1100 N/mm² surface-hardened (nitrated), one piece with finger grooves, minimum gauge 10 mm

Tools/Options

Special equipment

Clamping beam

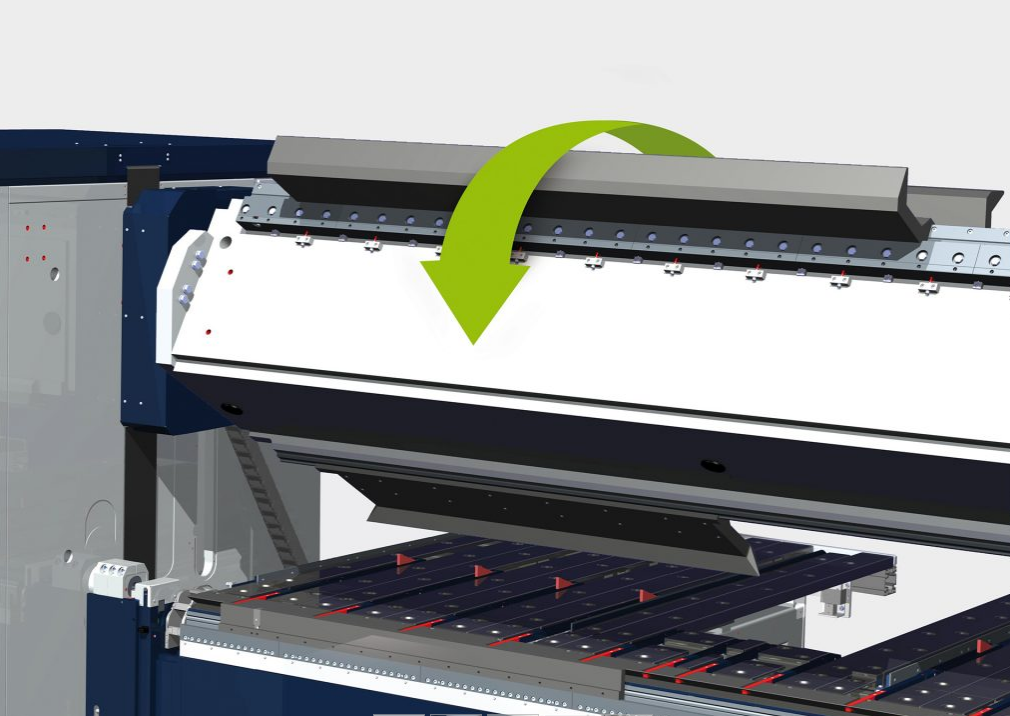

- Rotating clamping beam (48°/180°) for two tool stations incl., hydraulic tool clamping device on both sides

Folding beam

- Technology package Up and Down

- Technology package 3D (only with Up and Down)

- two servo drives for continuous commuting of the folding beam Up and Down

- Folding beam adjustment with servo drive and recirculating ball screws

Table and back gauge

- Back gauge extension to J- or U-gauge possible: Basis: motorized gauge up to 1600 mm, closed

- two fixed square arms (left and right side)

- two pneumatic pop-up square arms assembled on the aisle side, program-controlled

- Suction plates in gauge table with six suction units, program-controlled incl. positioning against the folding beam (only with Up and Down)

Software control

- PC Version (external programming), 1st license

- POS 3000 3D Graphic control

- DXF-Import and more processor capacity

- SCHRÖDER Unfold software (POS 3000 PC version necessary)

Safety and others

- Additional equipment for 2-man operation control following accident prevention rules required

- Operation from the rear, in addition to 2nd footswitch and protection via light barrier

- Customized light barrier package in front, horizontal light curtain aisle side, RFID switch through cabinet door

- Foot switch on the rail for lateral movement

- Voltage transformer 12 kVA

- Air conditioner

- Various bottom beam, folding beam, and clamping beam tools

New Features

PowerBend Professional is our revised folding machine with even more flexible application possibilities. It is the professional solution for thin sheet metal processing and continuous operation in large workshops, mid-sized companies and the industry.

- Clamping beam stroke 500 mm for product heights up to 250 mm

- two servo drives for continuous commuting of the folding beam Up and Down

- Servo-controlled folding beam adjustment

- More precise and faster positioning of the rotation point, servo-controlled

- Safety Package Plus

- LED status display

- Energy-efficient drives, according to IE3

- Optimized for Industry 4.0

- Prepared interface to product handling systems

- Completely new machine design and swivelling

Software

POS 2000 Professional:

The standard for industrial folding machines

The proven POS 2000 Professional makes programming a folding machine fast and comfortable. The desired program components can be selected from a comprehensive and expandable catalogue, and the angle and side dimensions can be easily changed by pressing the monitor.

The control software displays exactly what the machine is doing: The folding machine, workpiece, and tool are displayed schematically and updated for every bending step. Anyone who programs work preparation away from the machine can test the quality of their program using the bending simulation, which effectively avoids waste and delays during production.

The software not only controls the machine but also offers assistance to the user: all of the necessary operator activities, like turning, rotating, etc., are displayed for each bending step.

POS 3000 3D graphical control:

Interactive sheet design

POS 3000 3D graphical control is one of the most powerful controls on the market, and because both the hardware- and software come from a single provider, the PowerBend Professional and POS 3000 3D graphical control are a perfect match.

Working with POS 3000 is extremely comfortable:

Clearly, laid-out product selection, including a search function and navigation in submenus, enables the operator to select work steps and connect them in the production plan menu to create sequences.

The intuitive finger-activated drawing feature can quickly design individual product profiles. The exact dimensions may be entered and changed in the dimensioning menu. To check and coordinate together with the customer, the drawing may be output on paper using a printer.

Using the program created, the software generates the optimal sequence of bends, including automatic collision and threshold value monitoring. The folding angle and cut are corrected automatically using interpolation from the database.

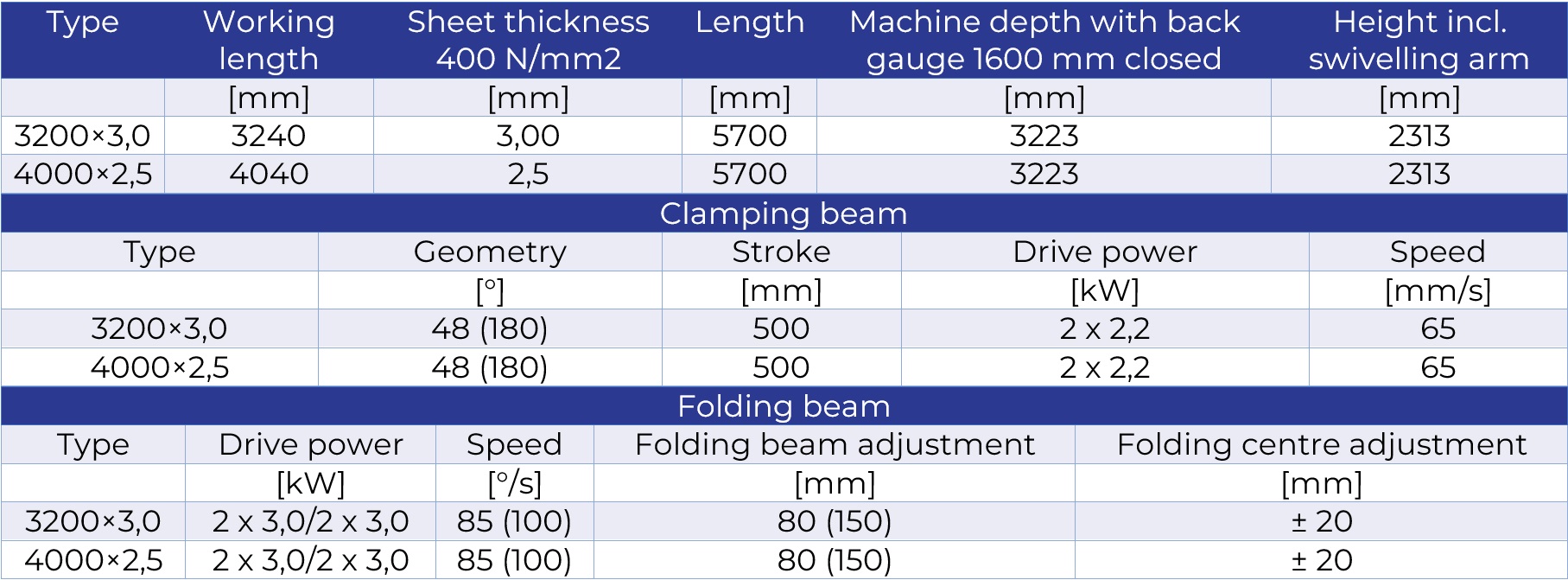

Technical Data

Success Stories

THE NEW PowerBend Professional is our revised folding machine with even more flexible application possibilities. It is a professional solution for thin sheet metal processing and continuous operation in large workshops, mid-sized companies and industries.