Details

The Schechtl MAB is the reinforced version of the MAX. It is even more solidly constructed, which means greater bending capacity. With a range of control systems and backgauge options, as well as a wide selection of rails, the MAB can be fully customised to suit your wishes.

Version:

MAB 200

The motorized swivel bending machine MAB 200 has a working length of 2040 mm. Due to its solid construction, it achieves a bending capacity of 3.00 mm steel.

MAB 250

The motorized swivel bending machine MAB 250 has a working length of 2540 mm. Due to its solid construction, it achieves a bending capacity of 2.50 mm steel.

MAB 310

The motorized swivel bending machine MAB 310 has a working length of 3100 mm. Due to its solid construction, it achieves a bending capacity of 2.00 mm steel.

MAB 400

The motorized swivel bending machine MAB 400 has a working length of 4040 mm. Due to its solid construction, it achieves a bending capacity of 1.50 mm steel.

Benefits:

Extremely high bending capacity

- Short bending times through extremely high swivel speed

- Time-saving through 1-man operation

- Minimal maintenance effort

- Versatile through a comprehensive range of accessories

Tools/Options

Subject to change

SHARP RAIL 20° R 1 MM OFFSET

- Sharp rail for the clamping beam

- Radius 1 mm

INSERT RAIL 10 MM

- Insert rail 68/10 mm for the bending beam

INSERT RAIL 24 MM

- Insert rail 68/24 mm for the bending beam

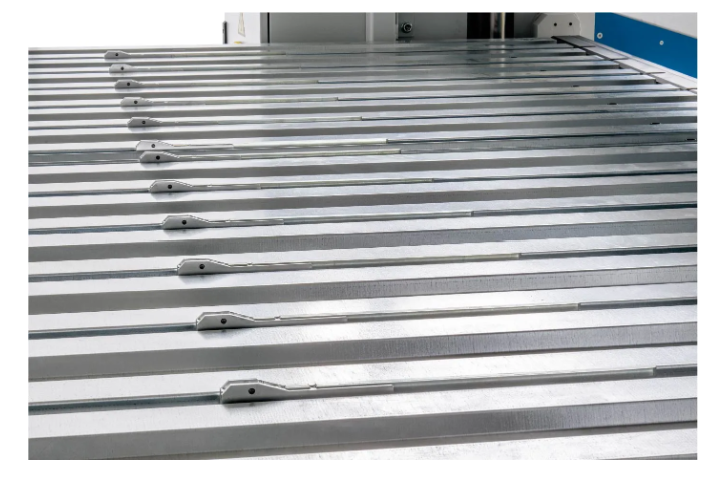

MOTORIZED BACKGAUGE 6-750 MM

- Motorized backgauge for precise

positioning of the sheets - With every new bending section, the backgauge fingers automatically move to the correct position

- For optimum adjustment to the workpiece, all

backgauge fingers are freely positionable over the entire bending length

MOTORIZED BACKGAUGE 6-1000 MM

- Motorized backgauge for precise

positioning of the sheets - With every new bending section, the backgauge fingers automatically move to the correct position

- For optimum adjustment to the workpiece, all backgauge fingers are freely positionable over the entire bending length

FOOTSWITCH

- Moveable foot switch as an operating element

for convenient 1-man operation - Note: In the case of 2-man operation, the accident insurance carrier requires a second foot switch

ADD-ONS – OPTIMISE YOUR MAB:

The following add-ons are possible depending on the version (working length/control):

ROLLER SHEAR RSL

For a precise cut!

- The simple and space-saving technology of the roller shear

allows you to cut the sheets directly at the swivel bending machine - The roller shear is equipped with a gas pressure spring

- This allows it to be folded away conveniently in upward direction

SWIVELLING FINGER BACKGAUGE 750 MM

Precise positioning of the sheets!

- The 750 mm backgauge is equipped with swivelling backgauge fingers

- These ensure precise bending over the entire working length

- The bending length is set by hand with a positioning wheel and measuring scale

MBA MOTORIZED BENDING BEAM LOWERING

- For faster bending sequences and added precision

CONICAL BACKGAUGE FINGERS

- Conical backgauge fingers allow easy

positioning in the case of conical bends

PC OFFLINE SOFTWARE

For efficient task preparation at your office workstation

- The PC offline software allows you to create

and edit profiles on the PC - The profile data can then be transferred

to the machine

Test it free of charge: demo licence required!

Test and experience the PC offline software for 30 days.

Simply request a free demo licence at service@schechtl.de.

ADVICE ON RAILS

- Round rails, goat’s foot tooling or special rails – we would be pleased to advise you on which product is best-suited for your requirements!

ADVICE ON BACK GAUGES

- Back gauges can be supplied in various versions

- We would be pleased to advise you on backgauge depths, forms etc.

Software

TheMABis available with the following controls:

ST

REDUCES SETUP TIMES. INCREASES VALUABLE PRODUCTION TIME.

Save profile sets in tables and repeat bending sequences with precision

Shaping profiles with the ST control gives you full control over machine functions and the bending result. Saving and loading the profile data in tables speeds up the production process and reproduces even complex profiles.

- Extremely clear and modern 10.4″ display

- The accustomed look & feel of the Schechtl S-Touch

- Save profile sets without limits

- Fast and easy-to-understand remote maintenance options

- 500 mm support rack for easy positioning of large-size metal sheets

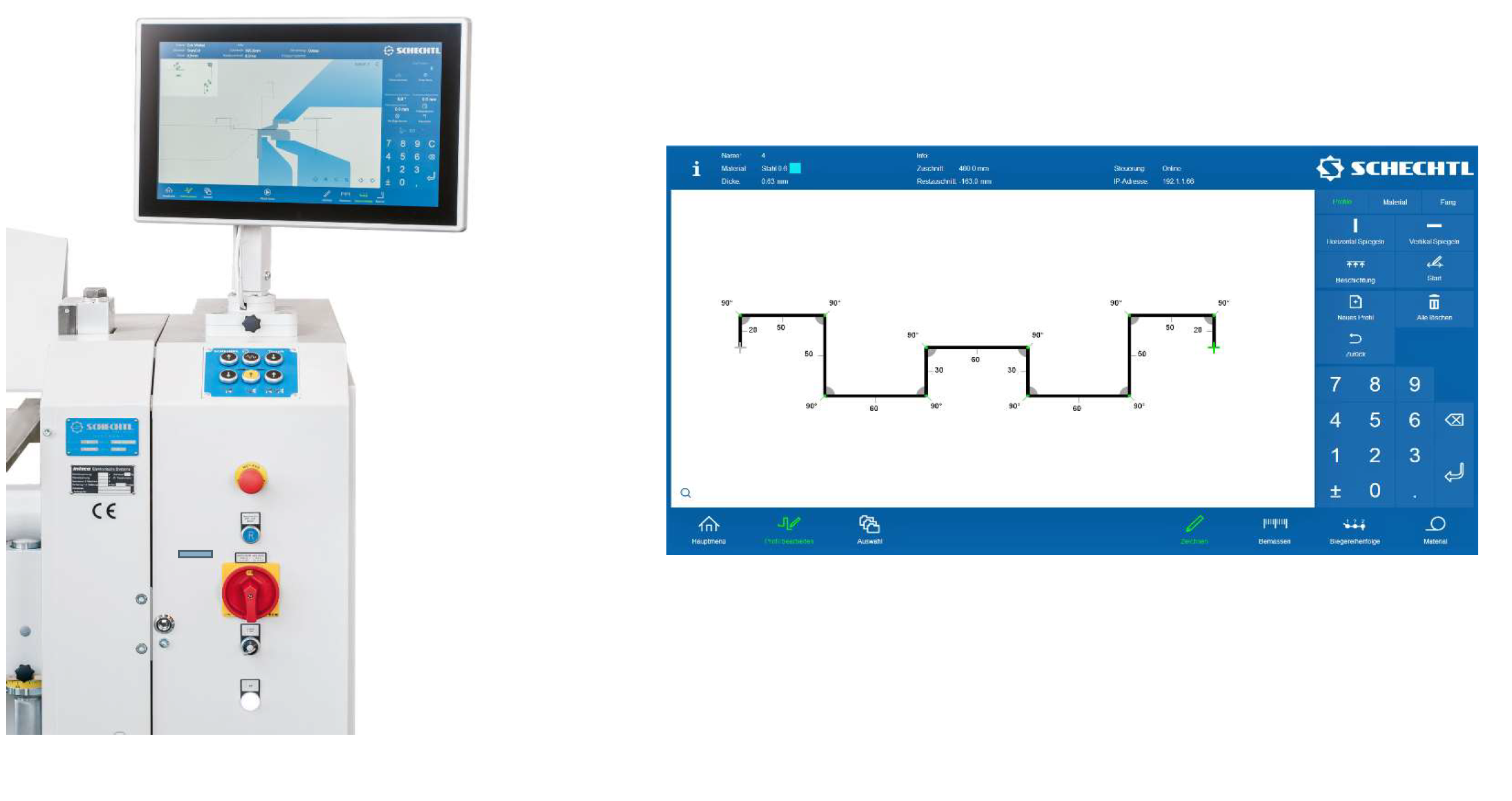

ECT

REDUCES SETUP TIMES. INCREASES VALUABLE PRODUCTION TIME.

Save profile sets in tables and repeat bending sequences with precision

incl. control of the motorised backgauge

Shaping profiles with the ECT control gives you full control over machine functions and the bending result. Saving and loading the profile data in tables speeds up the production process and reproduces even complex profiles.

- Extremely clear and modern 10.4″ display

- The accustomed look & feel of the Schechtl S-Touch

- Save profile sets without limits

- 30 bending angles per profile set

- Additional functions: Stamping and bending beam adjustment

- Teach-in of the bending beam

- Material, profile and tool management in the local database

CNC S-TOUCH

INTUITIVE. EASY. FASTER.

Draw complex bending sequences with your fingertips and graphic control

With the CNC S-Touch, sheet metal profiles are created simply and interactively with

your fingertip on the display and detailed in a dimensioning menu. The control system automatically recognises how the workpiece needs to be turned and repositioned and which tools are required.

- 21.5″ LCD Touch colour display with high-resolution graphics

- USB port for backup and transfer of programs

- Integrated WLAN

- Remote Support (TeamViewer)

- Graphic representation of the bending process

- Graphic representation of the position of the inserted sheet before every bend

- Operator guidance in text – each work step is explained visually

- Correct profiles directly by tapping the desired limb

- Bending angle correction can be programmed

- Set repetitions for special bend radii

- Quick entry mode and sketch selection

- Cutting program for roller shear

- Permanent storage of all programs

- Freely selectable program name

- Search for profiles via name

- Select from 16 languages

- Logging of machine data and runtimes

- Bending precision and convenience through motorised backgauge 1000 mm

Technical Data

The Schechtl MAB is the reinforced version of the MAX. It is even more solidly constructed, which means greater bending capacity. With a range of control systems and backgauge options as well as a wide selection of rails, the MAB can be fully customised to suit your wishes.