Details

The next generation for innovative coil processing. Markets are subject to permanent change. In sheet metal forming, this also leads to a higher complexity of products and processes. The efficient production of blanks for profiles and flashings requires effective, highly flexible and user-friendly solutions.

Slinet combines the best quality with easy use with the highest flexibility and automation.

The cut to length unit SLINET S 1.0 allows precise cuttings with lowest set up time. With its full automated up to 8 knife setting the SLINET S 1.0 allows an automated adjustment for slitting.

FULL AUTOMATIC KNIFE ADJUSTMENT

Precise positioning using an innovative clamping system. Optionally expandable to up to 8 full automatic positionable knife pairs. No reference cut is is necessary due to the upper knife shaft’s automatic lifting. No waste of length. Variable cutting gap and overlap adjustment for each material ensure the best material-related cutting results.

AUTOMATIC SHEET POSITIONING

Position sheet widths from 200 mm to 1250 mm automatically using the foot switch. Variable width alignment, including position brake. Extra hardened side guide made of special plastic for less abrasion.

INTUITIVE CONTROL VIA TOUCH PANEL

The standard control impresses with its user-friendliness and clear structure. Easy entry of the automatic slitting knifes. Adding different lengths with different quantities. Can be networked with Variobend long folding machines and double folders as well as other machines and programs. Control side freely selectable.

THE CUTTING DEVICE FOR PERFECT CROSS-CUTS

The incline position of the cutting blades ensures precise cuts: variable cutting gap and overlap adjustment for perfect cuts in a wide variety of materials. Roll knives are ground on both sides to double the operating time. The belt drive ensures speed and precision and is also maintenance-free. The linear rail technology guarantees a stable, quiet run of the cross-cut unit.

COMPACT SIZE

The compact design of the Slinet S 1.0 adapts perfectly to a wide variety of spaces. This means that even companies with limited space can benefit from the new technology. The large number of automations such as the automatic knife adjustment or the automatic side guide also allow further space savings to be achieved.

MASSIVE KNIFE SHAFT

A diameter of 125 mm guarantees perfect cutting results. Because of the big outside diameter the cutting quality will be maximized. In addition, the big outer diameter enables the individual knives to run longer.

Tools/Options

Additional slitting knife pair

Straightening Unit with 4 rolls

- The innovative 4 roll straightening unit allows an

automated change from convex to concave.

Guillotine

Digital package Slinet S1.0

• Networking Variobend and Slinet

• Label printer manual

• Synchronization of the labels with the respective cuts

• Including barcode reader

• Including interface for third-party software like Bendex, NuIT or Sema

• Including XML interface for integration into ERP systems or other software ASCO production software is ready

Software

Slinet Pro Touch

Easy and userfriendly

The SLINET Pro Touch combines efficiency and user-friendliness in an unprecedented relationship. The control which comes in standard stands for its userfriendliness and a clear structure.

SLINET PRO TOUCH AT A GLANCE:

- Functions such as the programming of partial cuts as a simulation can be made easily.

- The modern 15” flat screen in HD resolution permits ideal input and display.

- In basic mode, blanks for flashings can be made very easily.

- By using the material database, gap adjustments will be made automatically for each individual material.

- Easily by using the finger, you can add up to 9 strips.

- In addition, this mode can be used as a plate mode when a fully automated storage

system is installed.

Combines efficiency and user-friendliness in an unprecedented relationship

JOB MANAGEMENT

The job management allows you to add a number of folders and jobs. An optional list view helps the operator get a better overview. Different formats can be imported using the import function. In addition the export function allows the connection to different machines. Jobs can easily moved and copied by fingers.

DRAWING MODE

In the drawing mode, new jobs can be created. Add up to 9 different strips. In that mode, the optional brick cutting can be programmed. Choose the material from the matieral database or by directly clicking on the coil. In the simulation, the operator gets a graphic overview of the job. In connection with a fully automated coil storage system, the process will be done fully automated.

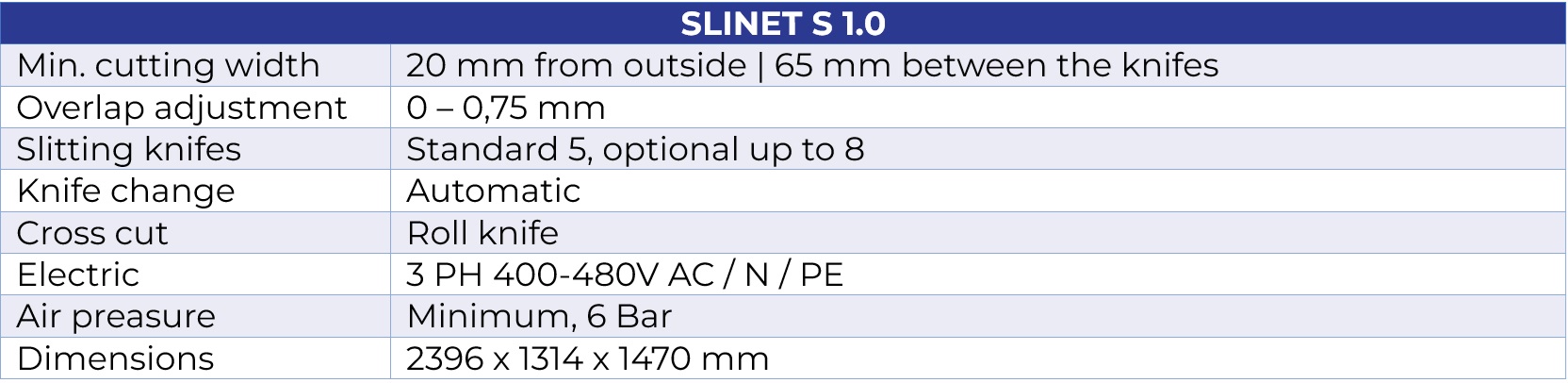

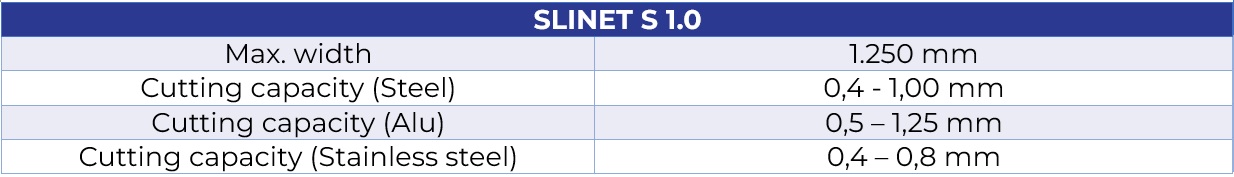

Technical data

The next generation for innovative coil processing. The cut-to-length unit SLINET S 1.0 allows precise cuttings with the lowest set-up time. With its fully automated up to 8 knife set, the SLINET S 1.0 allows an automated adjustment for slitting.