Details

The next generation of innovative coil processing

Markets are subject to permanent change.

In sheet metal forming, this also leads to an ever higher complexity of products and processes. The efficient production of blanks for profiles and flashings requires effective, high flexible and user friendly solutions.

Slinet combines the best quality with easy use with the highest flexibility and automation.

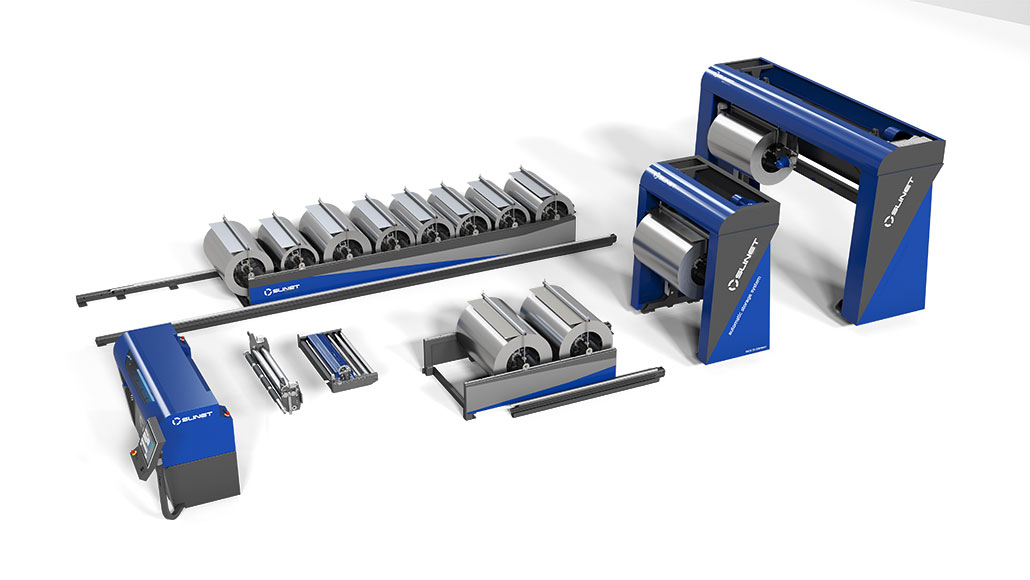

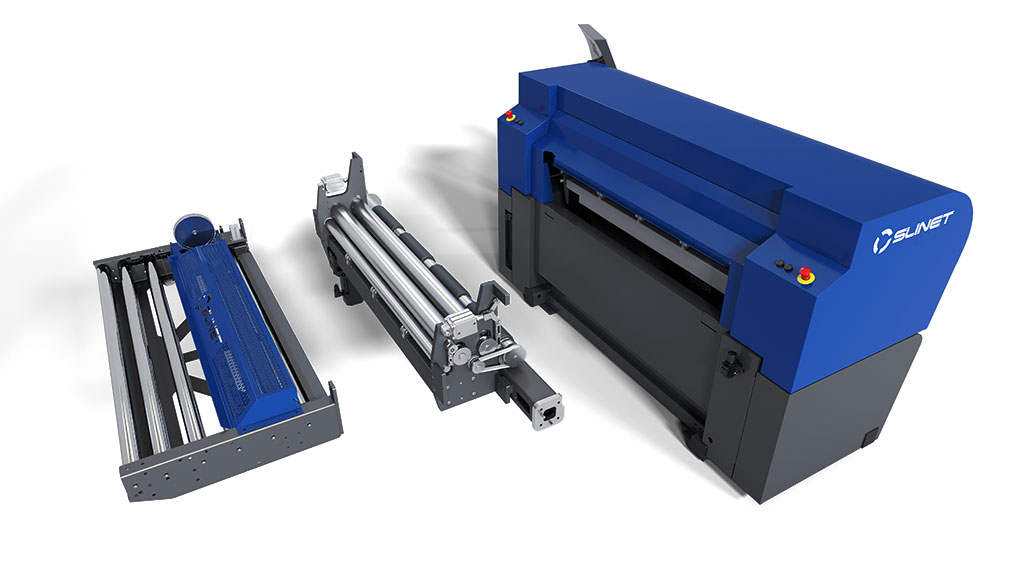

The modular system contains 3 modules that can be added flexibly to the required setting. The cut-to-length unit SLINET S 1.5 allows precise cuttings with the lowest setup time. With its fully automated up to 8 knife set, the SLINET S 1.5 allows an automated adjustment for slitting. The cross cut is made with an innovative roll knife. The system can be added by the automated 4-roll straightening unit. The next module which can be added is the fully automated coil storage system.

AUTOMATED KNIFE ADJUSTMENT

With it is up to 8 knife automated knife adjustment the production of blanks for profiles and flashings can be made fast and easy without manual knife adjustment.

CLAMPING SYSTEM

The knives can be locked and positioned perfectly thanks to the innovative clamping system.

OPTIONAL BRICK CUTTING

The optional brick cutting allows the optimal setting of orders within the coil by having minimum waste strips.

CROSSCUT

The cross-cut is made by a roll knife. This cut will not be made from the top as usual. The innovation of SLINET allows for cross-cutting from the bottom up. This innovation eliminates scratches that occur during material handling as the small grade goes up, not down.

DRIVE CONCEPT

With the parallel control of several axes and Servo technology, different positions can be made at the same time. This ensures high dynamical movements. The machine works fully electric.

STRAIGHTENING UNIT

The automated straightening unit can be ordered as optional. Done by 4 rolls this unit can switch between convex and concave automated.

AUTOMATIC SHEET POSITIONING

Position sheet widths from 200 mm to 1250 mm automatically using the foot switch. Variable width alignment, including position brake. Extra hardened side guide made of special plastic for less abrasion.

SLINET LABEL PRINTER

With the optional barcode label printer, you can network your production and minimize the risk of errors. Information such as the profile name or the order number can be placed arbitrarily and individually on the label. With the office software, a barcode can also be printed on the label which will allow the barcode scanner on the folding machine to open a profile directly. Not only profile characteristics (blank width, k-factor, taper values) but also parameters such as the crowning or the bending sequence defined in the office are thus automatically transferred with the barcode. The application of up to 9 labels is also very efficient. While the metal sheet is coming out, the labels are placed by means of a conveyor belt. When the sheet stops to cut it to length, up to 9 labels are then adhered to the respective strips at the same time. This makes for a very efficient system.

SLINET NESTING SOFTWARE

In order to produce small batch sizes optimally and effectively, several orders can be combined and the cut can be optimized, with the help of the Slinet Optimizer. With the optional partial cutting function, various lengths and widths of multiple jobs can be automatically optimized and cut with minimal waste. The optimization can be done in several ways.

The information (quantity, material, width, and length) is transferred from the office software. In addition, the bending sequence and conical dimensions can also be imported via barcodes.

Manual optimization via list input if there is no networked software.

Optimization takes place after the profiles have been transferred by third-party software (Bendex, NuIT, Sema)

Thus, the optimizer ensures flexible use across various software solutions. Networked manufacturing reduces the risk of errors and increases profitability.

Tools/Options

Extra Equipment:

Straightening Unit with 4 rolls

- The innovative 4-roll straightening unit allows an automated change from

convex to concave.

Straightening Unit with 6 rolls

- The innovative 6-roll straightening unit allows an automated change from

convex to concave.

Partial cut

Label Printer automatic Fully automatic 2-ton coil storage system

- During the cross-cut, up to 9 labels can be placed at the same time. This system

is highly efficient and fast.

Software optimizer

Guillotine

Touch Panel in 21,5 “

Foil unit

- Swivelling mandrel. Magnetic particle brake as tension control.

Digital package Slinet S1.5

• Networking Variobend and Slinet

• Including barcode reader

• Including interface for third-party software like Bendex, NuIT or Sema

• Including XML interface for integration into ERP systems or other software ASCO production software is ready

Slinet stands for the next generation of innovative coil processing.

Dynamic coil storage system – flexible to the requested requirements!

An industry innovation is the dynamic coil storage system by SLINET which is different than all existing systems on the market.

As standard, the patented system is made for eight 2-tone coils. The difference is that the storage system of SLINET does not work with fixed stations for each coil. The storage system works dynamically. By using each individual outside diameter of each coil, the storage system positions the coils not on a fixed station. It optimizes the space automatically. In the same space, up to 10 coils can be stored. The storage system is driven by a highly precise servo motor that works fully electric. Each coil axe has a unique ID. Depending on the remaining outside diameter of each coil the axes can be positioned

very close to create additional space. The system can be extended flexibly to the requested requirements.

Flexible positioning by unique axis ID.

Each axis includes a unique ID. This system ensures that a coil can be positioned anywhere within the storage.

Fully automatic 5-ton coil storage system

THE INDUSTRY-INNOVATIVE SLINET STORAGE SYSTEM

is also used for the 5-ton coil storage system. The standard version is designed for 16 5-ton coils in the double-row system. The storage system can also be extended to a three-track system. This then offers space for up to 24 coils. With the optional length extensions, the system can be expanded to more than 40 Coil storage spaces.

THE 5 TON STORAGE SYSTEM

from Slinet does not use fixed coil positions. The positions are dynamically adapted to the coil diameters. Thanks to this flexible storage system, it is possible to store more coils in the same area, depending on the outside diameters of the coils in the system. The storage system is controlled electrically by servo technology. Each coil axis contains a unique ID. In addition, each axis in the storage system is driven and has a braking system. The system can be adapted to your requirements and can be extended further for more coil storage.

Software

Slinet Pro Touch

Easy and userfriendly

The SLINET Pro Touch combines efficiency and user-friendliness in an unprecedented relationship. The control which comes in standard stands for its userfriendliness and a clear structure.

SLINET PRO TOUCH AT A GLANCE:

- Functions such as the programming of partial cuts as a simulation can be made easily.

- The modern 15” flat screen in HD resolution permits ideal input and display.

- In basic mode, blanks for flashings can be made very easily.

- By using the material database, gap adjustments will be made automatically for each individual material.

- Easily by using the finger, you can add up to 9 strips.

- In addition, this mode can be used as a plate mode when a fully automated storage

system is installed.

Combines efficiency and user-friendliness in an unprecedented relationship

JOB MANAGEMENT

Job management allows you to add a number of folders and jobs. An optional list view helps the operator get a better overview. Different formats can be imported using the import function. In addition the export function allows the connection to different machines. Jobs can easily moved and copied by fingers.

DRAWING MODE

In the drawing mode, new jobs can be created. Add up to 9 different strips. In that mode, the optional brick cutting can be programmed. Choose the material from the matieral database or by directly clicking on the coil. In the simulation, the operator gets a graphic overview of the job. In connection with a fully automated coil storage system, the process will be done fully automated.

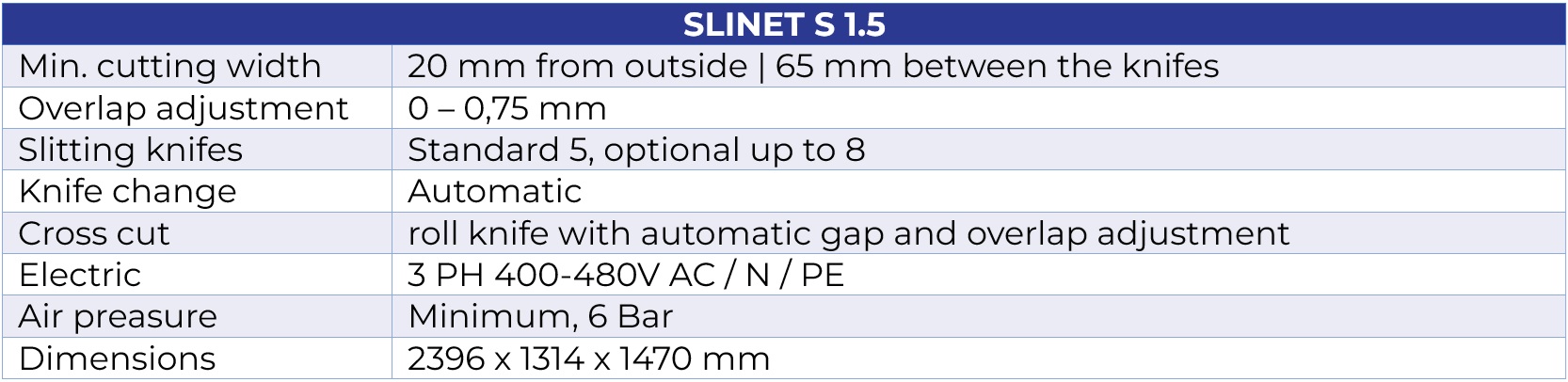

Technical data

The cut to length unit SLINET S 1.5 allows precise cuttings with lowest set up time. With its full automated up to 8 knife setting the SLINET S 1.5 allows an automated adjustment for slitting.